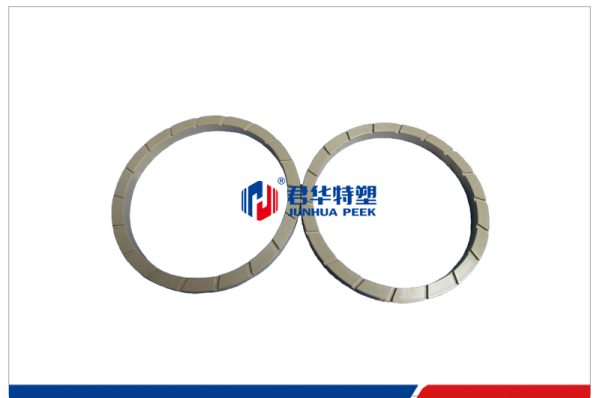

Alambre plano PEEK

1. PEEK flat wire for new energy vehicles

With the advancement of new energy electric vehicle technology, the 800v drive system has attracted more and more attention from manufacturers. One of the urgent problems to be solved for 800v motors is the high voltage stability of the winding flat wire. One of the more popular directions is to use PEEK extruded flat wire to replace the traditional enameled wire.

Compared with thick film enameled wire, PEEK flat wire has simpler production process, higher product stability, and high pressure resistance without repeated coating and baking. It can be bent repeatedly without damage during hairpin processing.

Junhua PEEK has been deeply involved in the PEEK industry for 16 years and can provide a full set of solutions for high-voltage resistant PEEK flat wires—raw materials with lower dielectric strength and precision extrusion process guidance for PEEK flat wires!

2. Introduction of PEEK (Polyetheretherketone) Cable

PEEK insulated wires have outstanding high temperature resistance, flame retardancy, radiation resistance and good mechanical properties, making them suitable for use as ultra-high temperature conductors in the aviation industry; they can be used as winding wires and connecting wires for submersible pump motors in the petroleum industry, and as winding coils for nuclear island drive mechanisms in atomic power plants for long-term use under irradiation conditions; PEEK insulated wires have excellent properties such as seawater resistance, light weight, small size and flame retardancy, making them suitable for use in ships; they are used in high-speed traction locomotives.

1. Halogen-free performance

PEEK material molecules do not contain halogen atoms, and do not produce acidic and toxic gases after combustion. It fully complies with EU RoSH and other environmental protection requirements and is an environmentally friendly material.

2. Volume resistance

In a very wide temperature range, ordinary PEEK polymer can still maintain a very high volume resistivity value. At 23°C, the volume resistivity of PEEK is above 6 × 1013 Ωm, at 140°C, its volume resistivity is above 8 × 1012 Ωm, and at 200°C, its volume resistivity is above 6 × 109 Ωm, and it still has excellent insulation properties.

3. Surface resistance

The surface resistivity of PEEK at 25°C and 50% humidity reaches 2.0 × 1016 Ω, which is better than fluoroplastics, polyamide, polyimide and other plastics.

4. Dielectric constant and dielectric loss factor

The dielectric constant of PEEK5600G is only 2.7, which is slightly higher than polyethylene (PE) and fluoroplastics, but much lower than polyvinyl chloride (PVC). In the frequency range of 109 Hz, ordinary PEEK polymer has good electrical properties. Many of the electrical properties of this material meet the typical properties of thermoplastic materials, and PEEK polymer also maintains these excellent insulation properties over a very wide temperature and frequency range. Below 140°C, the tanδ loss of PEEK material is small. In Figures 4 and 5, PPS is polyphenylene sulfide, PES is polyethersulfone, PC is polycarbonate, and PSU is bisphenol A type polysulfone.

5. Heat resistance

PEEK polymer has a glass transition temperature of 143℃. Since it is a semi-crystalline thermoplastic material, it can still maintain excellent mechanical properties near the melting point of 343℃. Its fatigue resistance and creep resistance are higher than those of thermoplastics.

6. Flame retardancy

PEEK is self-extinguishing. Without adding flame retardant, the UL standard reaches 94V-1 (thickness 0.3 mm), 94V-0 (thickness 1.5 mm), and 94V-5 (thickness 3.2 mm). In addition, the amount of smoke generated during combustion is very small.

7. Chemical resistance

PEEK only dissolves in concentrated sulfuric acid and has good chemical resistance (including lubricating oil, ATF oil, impregnation paint, epoxy resin paint), especially at high temperature, it is much better than polyimide in acid and alkali resistance. At the same time, PEEK has a very low water absorption rate, and the saturated water absorption rate at 23℃ is only 0.5%. It also has good hot water resistance and can be used in pressurized hot water or steam at 300℃.

8. Radiation resistance

It has a strong resistance to gamma radiation, which exceeds the radiation resistance of polystyrene among general resins. It can be made into wires that can still maintain good insulation performance when the gamma radiation dose reaches 1100 Mrad

2. Process Capability

Flat electromagnetic wire (reserved function): 3.30mm*11.40mm (within the range of 2.0mm*12.0mm), coating thickness: 0.10~0.70mm;