作者: junhua

Mercedes-Benz utiliza PEEK para reemplazar engranajes metálicos

Evonik has recently developed a PEEK molding compound with high friction performance and high durability. Gears made of PEEK can meet the harsh application environment of internal combustion engines and replace metal gears. It is understood that there is a component in the internal combustion engine called a mass balancer, which ensures the smooth operation of the internal combustion engine by reducing the vibration caused by the piston on the surrounding structure. The mass balancer gear is often in contact with the engine oil and exposed to high temperatures of up to 130 degrees Celsius, and is usually made of metal. PEEK is now used to manufacture low-wear outer ring gears for plastic gears in mass balancers. This…

2022-03-14 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Cuanto más avanzamos, más cerca están nuestros sueños: Conferencia Anual de Ventas 2022

2022 Annual Sales Conference Sign-in Time flies, and the year 2021 is already far away from us. Looking back on the past year, Junhua PEEK has won many awards, achieved remarkable results and progress in all aspects, and its shipment sales are even more It reached a new high, breaking through 167 million yuan. In order to better formulate the company’s 2022 sales strategic goals and five-year strategic development plan, Junhua PEEK hereby solemnly convenes the 2022 Annual Sales Conference. At 8:00 on February 26, the conference host Ms. Feng announced the opening of the conference on time, warmly welcoming colleagues from Jiangsu and friends from Shandong to attend this conference! And announced today’s meeting agenda: 2021 Junhua Chronicles –…

2022-03-02 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Cómo calcular el peso de una varilla de PEEK

La fórmula de cálculo del peso de la varilla de PEEK es: masa = volumen x densidad. La densidad del PEEK puro es aproximadamente 1,3 y la del PEEK modificado es aproximadamente 1,4. Sin embargo, cabe señalar que el diámetro exterior de la varilla de PEEK es generalmente mayor. la calibración, por lo que el peso de una sola varilla debe basarse en el diámetro exterior real.

2022-01-20 | Preguntas frecuentes | Etiquetas: Perfiles de PEEK, Varillas de PEEK

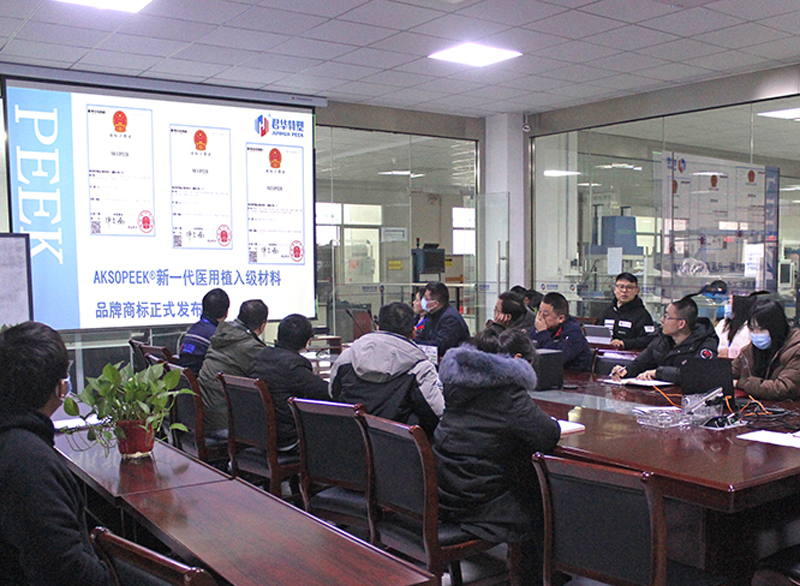

Se lanza oficialmente AKSOPEEK, una nueva generación de materiales médicos implantables

At present, my country’s implant-grade PEEK materials mainly rely on imports. Based on market feedback and national R&D project needs, Junhua PEEK launched the domestic implant-grade PEEK material brand AKSOPEEK series products. At the same time, in response to the needs of national intellectual property protection, the company’s products further strengthened management when they enter the market to enhance product awareness. The company applied to the State Administration for Industry and Commerce for the AKSOPEEK trademark, and was approved for registration and issued a certificate by the Trademark Office of the State Administration for Industry and Commerce in December 2021. AKSOPEEKBrand Value 01. AKSO is full of value and profound meaning. In ancient Greek mythology, it is the representative…

2022-01-15 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

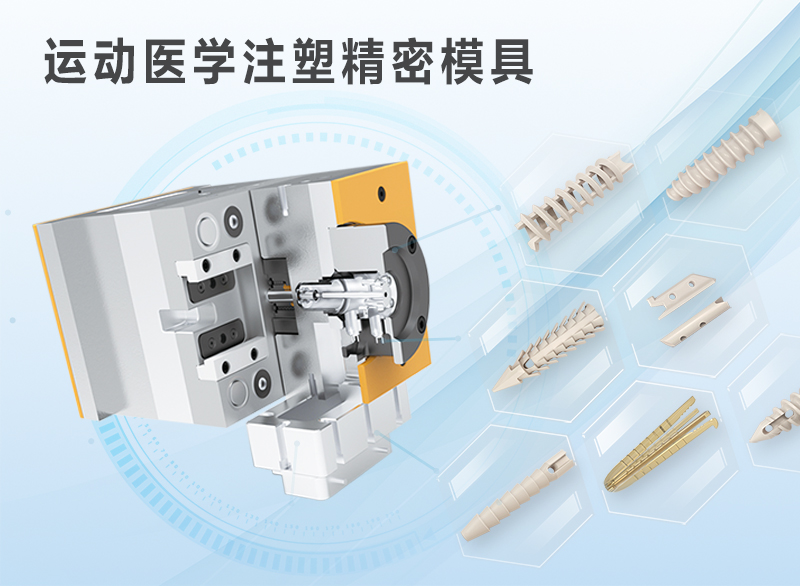

Molde de precisión para inyección de PEEK para medicina deportiva

Since the 1970s, joint surgery has made great progress in the United States and other countries. In the past few decades, arthroscopy has had a revolutionary impact on the diagnosis and treatment of intra-articular diseases. However, the first generation of shoulder arthroscopy equipment uses stainless steel and titanium anchors, both of which will fail due to the breakage of the sutures in the metal eyelets. For this reason, the medical device industry has made many attempts and designed a variety of injection molded products – implant-grade PEEK anchors. PEEK is strong and tough, and can provide strength similar to that of metal. If a revision surgery is required, it can be drilled through without increasing the difficulty of the surgery….

2022-01-11 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

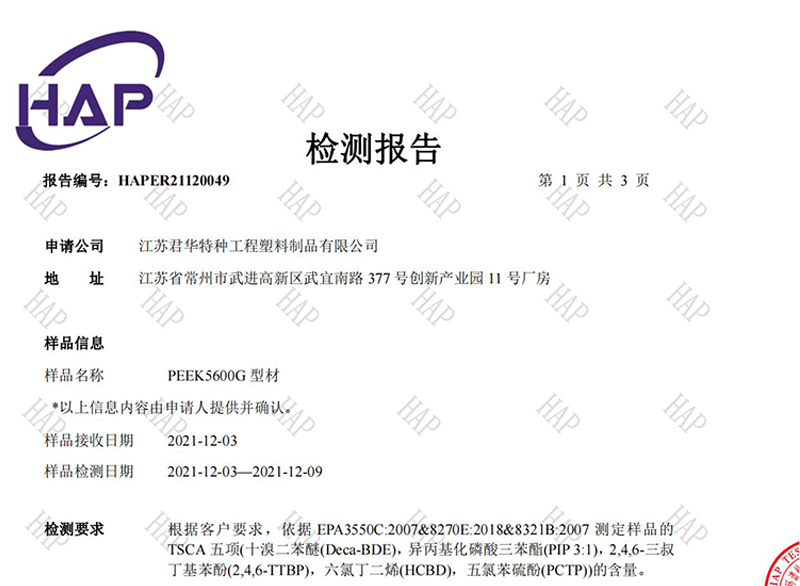

Las pruebas PEEK de Junhua cumplen con la TSCA

PRRT 01. Definition and History of TSCA TSCA stands for Toxic Substances Control Act, or TSCA for short. It was enacted by the U.S. Congress in 1976 and took effect in 1977. The U.S. Environmental Protection Agency (EPA) is responsible for its implementation. The Act aims to comprehensively consider the environmental, economic and social impacts of chemical substances circulating in the United States and prevent «unreasonable risks» to human health and the environment. After several revisions, TSCA has become an important regulation for the effective management of chemical substances in the United States. For companies whose products exported to the US market fall into the TSCA regulatory category, TSCA compliance is a prerequisite for normal trade in US products. These…

2022-01-07 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Junhua PEEK participó en la formulación de estándares nacionales para resina de polieteretercetona (PEEK)

National Standard for Polyetheretherketone (PEEK) Resin The National Standardization Administration issued Document No. 40 [2019] «Notice of the National Standardization Administration on Issuing the Fourth Batch of Recommended National Standard Plans in 2019», which issued the national standard formulation plan for «Polyetheretherketone (PEEK) Resin», with project number 20194348-T-606. The standard plan project was proposed by the China Petroleum and Chemical Industry Federation, under the jurisdiction of the Plastics Standardization Technical Committee, and implemented by the Engineering Plastics Sub-Technical Committee of the Plastics Standardization Technical Committee. Junhua PEEK participated in the online video discussion on the draft national standard for polyetheretherketone (PEEK) resin and the 2021 Annual Meeting and Standard Review Meeting of the Engineering Plastics Branch of the Plastics Standardization…

2022-01-04 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Materiales de grado de implantes médicos de nueva generación de AKSOPEEK

AKSOPEEK As a member of special engineering plastics, PEEK (polyetheretherketone) has excellent comprehensive performance (easy molding, corrosion resistance, etc.) compared with other special engineering plastics (such as PPS, PAI, PI, PTFE, etc.). Its good biocompatibility, high purity, chemical inertness and elastic modulus similar to that of human bones have earned it a reputation as a new generation of orthopedic implant materials after titanium alloys. ▲ Comparison of mechanical properties of different implant materials and natural bone[1] The early medical application of PEEK was in dentistry, with dental bridges and crowns being its typical applications. With the deepening of understanding and research on PEEK, the scope of its application has also been broadened. PEEK bridges and crowns In skull repair…

2021-12-16 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Resina PEEK utilizada por Malema para caudalímetros Coriolis desechables

Due to its excellent physical properties, PEEK resin is used by Malema in disposable Coriolis flow meters to improve measurement accuracy and cleanliness. On October 8, 2021, Alpharetta medical PEEK (polyetheretherketone) resin in Georgia, USA was selected by Malema for the production of disposable Coriolis flowmeters, which played a vital role in the production of the new crown vaccine. Because PEEK material has excellent physical properties, such as extremely high Young’s modulus – which helps ensure the measurement accuracy of the sensor and the integrity of the plastic in a continuous vibration environment. PEEK resin meets the USP Class VI standard, can withstand gamma ray sterilization, and has extremely low levels of leachables and extractables, which helps achieve high cleanliness….

2021-12-11 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Cómo distinguir PEEK de TPU

TPU, also known as thermoplastic polyurethane elastomer rubber, is an elastomer that is plasticized by heating and dissolved by solvents. It has excellent wear resistance, excellent ozone resistance, high hardness, high strength, good elasticity, low temperature resistance, oil resistance, chemical resistance, and environmental resistance. It is widely used in the fields of footwear, cables, clothing, automobiles, medicine and health, pipes, films, sheets, etc. However, PEEK is different from TPU. PEEK is a special engineering plastic called polyetheretherketone. PEEK has a series of excellent comprehensive properties such as high temperature resistance, wear resistance, corrosion resistance, and high strength. It has been successfully and widely used in aerospace, automotive, electronic semiconductor, electromechanical and other industries with high requirements. TPU is an elastomer…

2021-11-25 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Aplicación del tubo de tres lúmenes de PEEK en instrumentos quirúrgicos de ablación por radiofrecuencia

Junhua PEEK three-lumen PEEK capillary tube is used in gastrointestinal minimally invasive surgery. Gastrointestinal radiofrequency ablation surgical instruments are a new type of minimally invasive surgical instruments. Designers use the structure and material of PEEK three-lumen tubes to ensure the use effect of the instrument. The three holes in the PEEK three-lumen tube are respectively equipped with: 1 cooling water, 2 sensors, and 3 electrode circuits. PEEK material has good heat resistance and insulation properties, is both rigid and tough, and can achieve good guidance, bringing good news to patients undergoing radiofrequency ablation surgery in the gastrointestinal tract and other organs.

2021-10-28 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Viajando juntos y reuniendo fuerzas: los empleados de Jiangsu Junhua viajan

Thank you for your company along the way, let us work together to realize the Junhua PEEK dream! Pleasant and comfortable travel Nothing is more Spend it in a place with sunshine, lakes and bamboo forests. The sun is shining, everything is growing, It is a good time for outings. Bring a beautiful mood and start a relaxing journey. A change from the seriousness and busyness of daily work, Along the way, there were laughter and joy. The distance between each other was suddenly shortened! In recent years, the scale and strength of Junhua PEEK have been continuously developing and growing, which is inseparable from the efforts of every employee of the company. In order to create a…

2021-06-07 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa