作者: junhua

Hoja de PEEK

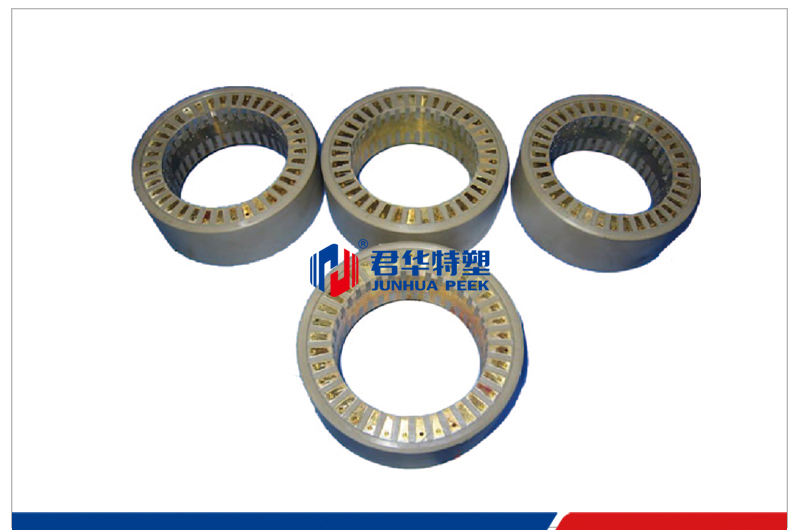

Junhua PEEK ha cooperado con Arabia Saudita, PetroChina, Sinopec, la Universidad del Petróleo, Xi’an y otros clientes para producir PEEK resistente al desgaste por empuje…

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Bloque de sello de soporte de cara final de PEEK

Junhua PEEK ha cooperado con Arabia Saudita, PetroChina, Sinopec, la Universidad del Petróleo, Xi’an y otros clientes para producir PEEK resistente al desgaste por empuje…

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Botas de émbolo PEEK

Junhua PEEK ha cooperado con Arabia Saudita, PetroChina, Sinopec, la Universidad del Petróleo, Xi’an y otros clientes para producir PEEK resistente al desgaste por empuje…

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Placa de distribución de PEEK

Junhua PEEK ha cooperado con Arabia Saudita, PetroChina, Sinopec, la Universidad del Petróleo, Xi’an y otros clientes para producir PEEK resistente al desgaste por empuje…

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Industria petroquímica

PEEK high-performance materials combine chemical resistance, electrical properties, wear resistance, hydrolysis resistance and high temperature resistance. They are increasingly being widely adopted by the oil industry to improve operating performance and reduce the risk of downtime associated with component failure. PEEK materials have unique comprehensive properties and bring lower electrical interference; PEEK materials can also withstand various corrosive chemicals, solvents and lubricants used in the oil industry. Therefore, PEEK materials can be used in subsea integrated pipe bundles, pipelines, marine risers, and drill pipes. Digital logging, electrical connectors, seals, support rings, plugs and packers, wires and cables, compressors, downhole sensors, fracturing balls, cable ties, stabilizers, bearing bushings and gears, etc.

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Barril de presión PEEK

Los materiales de alto rendimiento PEEK combinan resistencia química, propiedades eléctricas, resistencia al desgaste, resistencia a la hidrólisis y resistencia a altas temperaturas, y son cada vez más populares…

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Material PEEK petroquímico

PEEK high-performance materials combine chemical resistance, electrical properties, wear resistance, hydrolysis resistance and high temperature resistance. They are increasingly being widely adopted by the oil industry to improve operating performance and reduce the risk of downtime associated with component failure. PEEK materials have unique comprehensive properties and bring lower electrical interference; PEEK materials can also withstand various corrosive chemicals, solvents and lubricants used in the oil industry. Therefore, PEEK materials can be used in subsea integrated pipe bundles, pipelines, marine risers, and drill pipes. Digital logging, electrical connectors, seals, support rings, plugs and packers, wires and cables, compressors, downhole sensors, fracturing balls, cable ties, stabilizers, bearing bushings and gears, etc.

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Etiqueta electrónica PEEK para identificación de tuberías de perforación

PEEK high-performance materials combine chemical resistance, electrical properties, wear resistance, hydrolysis resistance and high temperature resistance. They are increasingly being widely adopted by the oil industry to improve operating performance and reduce the risk of downtime associated with component failure. PEEK materials have unique comprehensive properties and bring lower electrical interference; PEEK materials can also withstand various corrosive chemicals, solvents and lubricants used in the oil industry. Therefore, PEEK materials can be used in subsea integrated pipe bundles, pipelines, marine risers, and drill pipes. Digital logging, electrical connectors, seals, support rings, plugs and packers, wires and cables, compressors, downhole sensors, fracturing balls, cable ties, stabilizers, bearing bushings and gears, etc.

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Materiales PEEK para la industria petroquímica

PEEK high-performance materials combine chemical resistance, electrical properties, wear resistance, hydrolysis resistance and high temperature resistance. They are increasingly being widely adopted by the oil industry to improve operating performance and reduce the risk of downtime associated with component failure. PEEK materials have unique comprehensive properties and bring lower electrical interference; PEEK materials can also withstand various corrosive chemicals, solvents and lubricants used in the oil industry. Therefore, PEEK materials can be used in subsea integrated pipe bundles, pipelines, marine risers, and drill pipes. Digital logging, electrical connectors, seals, support rings, plugs and packers, wires and cables, compressors, downhole sensors, fracturing balls, cable ties, stabilizers, bearing bushings and gears, etc.

2024-07-19 | Aplicación, Petroquímico, Productos | Etiquetas: Petroquímica Industria

Buje de PEEK para impulsor de bomba de agua de automóvil

Buje de PEEK para impulsor de bomba de agua de automóvil

2024-07-19 | Aplicación, Productos, Vehículos de nueva energía | Etiquetas: Industria de vehículos de nueva energía

Bujes de PEEK resistentes al desgaste a altas temperaturas para automóviles

1: Wear-resistant sleeve for automobile water pump The car water pump is responsible for regulating the coolant within a certain range to ensure the normal operation of the engine. When rotating at high speed, it comes into contact with the seal, housing, and coolant, and is constantly worn. The PEEK-5600CF30 sleeve has self-lubricating properties. Wear and corrosion resistance, fully competent and effectively increase the service life of the pump body. 2: High temperature wear-resistant sleeve High temperature wear-resistant bushings have excellent wear resistance, very low friction coefficient, and high PV value, and are very suitable for wear resistance and harsh conditions. 3: Brake pump blade It is an excellent metal with good dynamic fatigue resistance, corrosion resistance and good wear…

2024-07-19 | Aplicación, Productos, Vehículos de nueva energía | Etiquetas: Industria de vehículos de nueva energía

Cuchilla PEEK para bomba de freno de automóvil

El PEEK tiene buena resistencia a la fatiga dinámica y a la corrosión bajo operación a alta temperatura, y tiene una excelente resistencia al desgaste en condiciones sin lubricación.

2024-07-19 | Aplicación, Productos, Vehículos de nueva energía | Etiquetas: Industria de vehículos de nueva energía