年份: 2016

Características y ventajas del PEEK

Características y ventajas del PEEK

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Indicadores de rendimiento de PEEK

Main grades of PEEK and their typical performance indicators Item Test standards or instruments unit PEEK5600G PEEK5600GF30 PEEK5600CF30 PEEK5600LF30 Pure resin Contains 30% glass fiber Contains 30% carbon fiber Contains 30% (carbon fiber + graphite + PTFE ) Color - Original color, grayish yellow or black Original color, grayish yellow or black black black Actual density ISO 1183 g/cm3 1.3±0.02 1.5±0.02 1.4±0.02 1.43±0.02 Water absorption rate (25 ℃ .24Hrs) ISO 62 % 0.15 0.11 0.06 0.06 Molding shrinkage ( 25-24 ℃) 3mm thickness, 170 ℃ flow direction 3mm, 170 ℃ , % 1.2 0.4 0.1 0.3 Perpendicular to the flow direction (larger after saturated crystallization) % 1.5 0.8 0.5 0.5 Melting point ISO 1133 ℃ 343 343 343 343 Continuous…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

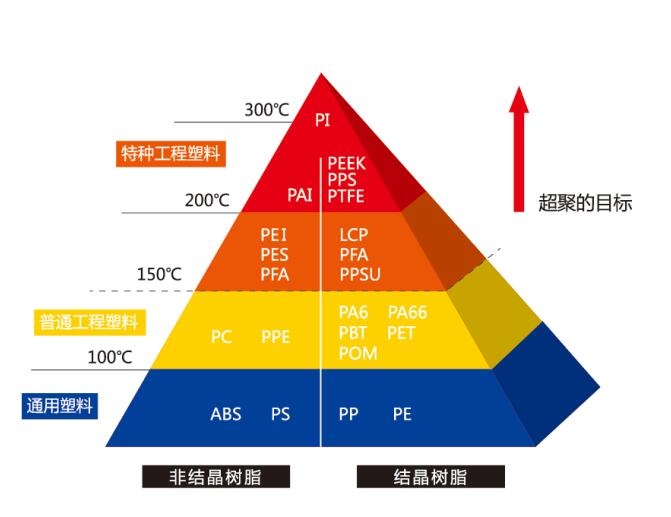

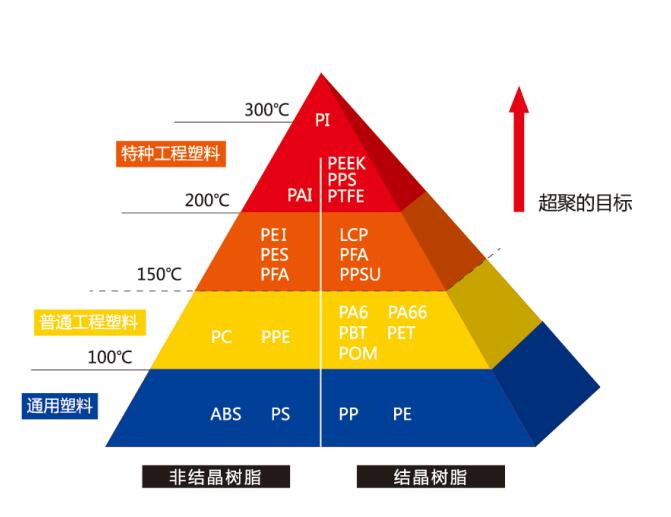

Ventajas características de PI

Datos técnicos de la empresa Changzhou Junhua: PI Características Ventajas Descripción general de los materiales PEEK y PI , características, ventajas y desventajas 1. Descripción general del material El PEEK y el PI son materiales de alto rendimiento sintetizados y patentados. Poseen excelentes propiedades integrales que otros plásticos generales no pueden igualar entre los polímeros de alto rendimiento. Ofrecen un rendimiento excepcional, adecuado para diversos entornos hostiles, y se han utilizado con éxito y ampliamente en diversas industrias, como la aeroespacial, la automotriz, la de semiconductores electrónicos y la electromecánica, con requisitos relativamente exigentes. Son los materiales preferidos por los usuarios para desarrollar nuevos productos y mejorar su vida útil y fiabilidad. 2. Características y ventajas ◆ Resistencia a altas…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Índice de rendimiento de PI

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Resistencia a altas y bajas temperaturas del PEEK

Junhua PEEK Technical Data: PEEK has excellent high and low temperature resistance 1. The meaning, measurement methods and results of several heat-resistant performance indicators of PEEK: glass transition temperature, melting point, heat deformation temperature, continuous use temperature, thermal expansion coefficient, thermal conductivity. 2. Note: The thermal conductivity of PEEK composite materials containing glass fiber and carbon fiber is higher than that of pure PEEK, but the thermal expansion coefficient becomes smaller. 3. Comparison of heat deformation temperature of PEEK and other high-performance materials 4. Comparison of long-term use temperature of PEEK and other high-performance materials Bar chart Heat aging characteristics of PEEK and its composite materials 5. PEEK and its composite materials have excellent heat aging resistance. Whether it is…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Características de fricción y desgaste del PEEK

Junhua PEEK Technical Data: Introduction to the Self-lubrication, Friction and Wear Characteristics of PEEK 1. Friction is the interaction between contacting surfaces when they move relative to each other under the action of external forces. When observing the surface of a material that looks very smooth under a microscope, you can see obvious bumps and depressions. Therefore, if two materials are in contact and move relative to each other, the rough particles on the surfaces of the two materials will collide with each other, and the disappearance of the rough particles can be defined as wear. 2. PEEK has outstanding sliding properties among all plastics. It can provide excellent wear resistance under various temperatures, pressures and relatively rough contact surfaces….

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Los productos PEEK son dimensionalmente estables

Los productos PEEK son dimensionalmente estables

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Propiedades retardantes de llama del PEEK

Brief introduction to PEEK’s flame retardant, low smoke and low toxic gas emission characteristics PEEK is difficult to burn in general situations. Even when it burns, the amount of smoke and corrosive gas produced is very small. PEEK has the advantages of flame retardancy, low smoke and low toxic gas emission. The details are as follows: 1. Flame retardancy: The flammability of a material is the ability to sustain combustion after obtaining high energy from a mixture of oxygen and nitrogen. The recognized standard for measuring flammability is UL94, which is to ignite a vertical sample of a predetermined shape and then measure the time it takes for the material to automatically extinguish. The test result for PEEK is V-0,…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Breve introducción de las propiedades eléctricas del PEEK

PEEK has excellent electrical insulation properties. Usually, the volume resistivity can reach 10 15 -10 16 megohms, and it can maintain a small dielectric constant and dielectric loss in a wide temperature and frequency range. Comparison of surface resistivity of PEEK and other engineering plastics (see the figure in the download attachment);

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Resistencia a la corrosión del PEEK

1. PEEK can tolerate almost any chemical except fuming concentrated sulfuric acid, and it can maintain good chemical stability even at higher temperatures. It has strong resistance to chemical corrosion and is usually used to manufacture parts that work in harsh environmental conditions or need to withstand frequent disinfection (such as chemical storage tanks and medical devices that need to be disinfected with strong oxidant hydrogen peroxide). 2. Although PEEK polymer has been widely regarded as a material that can withstand extremely strong chemical corrosion, of course, whether PEEK can withstand a certain corrosive medium is also related to the crystallinity of the PEEK parts, the residual internal stress, and the temperature and concentration of the medium in contact with…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

PEEK ha pasado la prueba y la certificación.

Junhua PEEK always adheres to the principle of taking science and technology as the guide, taking the road of scientific and technological innovation, and has maintained long-term technical exchanges and cooperation with Jilin University and Nanjing University of Technology in China. In 2014, the company established the High-Performance Special Engineering Plastics Engineering Technology Research Laboratory in Wujin District, Changzhou City, and continuously carried out the application research and development of PEEK with the orientation of meeting customer needs. The company currently has 16 patented technologies: six of which have obtained invention patents, including the production equipment for continuous extrusion of PEEK sheet and tube profiles, PEEK rotors and their preparation methods. In 2013, the company formulated the «PEEK Profile and…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material

Introducción a la resistencia a la hidrólisis del PEEK

Company technical data: PEEK has outstanding hydrolysis resistance 1. PEEK has the best resistance to hot water and steam among all engineering plastics. PEEK polymer and its composite products (i.e., modified by glass fiber, carbon fiber, graphite, PTFE, etc.) can resist chemical damage caused by water or high-pressure steam, can be used continuously under hot water and high-pressure steam conditions, and still maintain good mechanical properties. 2. PEEK’s good hydrolysis resistance enables PEEK and its composite products to withstand repeated high-temperature and high-pressure steam sterilization, which other thermoplastics cannot withstand for a long time, so it has been successfully used in harsh areas such as medical equipment. 3. Mechanical properties change test data of PEEK and its composite materials under…

2016-08-29 | Rendimiento del material | Etiquetas: Propiedades del material