日期: 2016-09-01

Materiales modificados con PEEK de alto rendimiento: permiten una reducción eficiente del peso y de los costes de los cuerpos de las chaquetas de los transbordadores

In the weaving process of fabrics, the shuttle clamp plays a key role in high-speed reciprocating transmission of weft yarns. It not only has to withstand a linear speed of 30m/s, 7-8 times/s of high-speed reciprocating motion, but also has to withstand motion impact. On the other hand, during long-term use, the shuttle clamp component is not allowed to affect the photoelectric detection system’s broken end detection due to its surface wear and whitening. Therefore, this component places extremely strict requirements on the mechanical strength and impact resistance of the material. Usually, shuttle clamps are composed of a metal or plastic housing and a metal holder. As an ideal alternative to metal materials, using high-performance PEEK modified material solutions, the…

2016-09-01 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Aplicación de la fibra de poliimida (PI) en el sector textil

The application of polyimide (PI) fiber in the field of clothing is the first in the world to apply this aerospace and military technology to the field of civilian textiles. PI has excellent resistance to high temperatures, low temperatures, solvents, radiation, and outstanding mechanical strength and dielectric properties. It is now widely used in many high-tech fields such as aerospace, automobiles, electronic semiconductors, welding and cutting, and electrical appliances. Yilun 95 polyimide clothing fiber developed by Changchun Gaoqi Polyimide Material Company has native flame retardant, warmth retention, antibacterial and antifungal, anti-mite, anti-mite, and strong native far-infrared function. Currently, there are cold-proof clothing, thermal underwear, knitted clothing, outdoor products and functional therapeutic products. The company focuses on the application, research and…

2016-09-01 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Impresión 3D de plásticos de ingeniería de ultraalta temperatura a 200 °C

It is reported that Professor Toshiki Niino of the Institute of Production Technology at the University of Tokyo and others have successfully used 3D printers to complete the three-dimensional shaping of super engineering plastics with heat resistance of more than 150°C. Compared with existing processing methods such as cutting and injection molding, it has a strength of about 80% and can process complex shapes, which is conducive to the production of engine peripheral parts for automobiles and aircraft that require high temperature resistance. The three-dimensional shape was successfully completed using polyphenylene sulfide (PPS) with a melting point of 280°C and a heat resistance of 150°C and polyetheretherketone (PEEK) with a melting point of 360°C and a heat resistance of 200°C….

2016-09-01 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Evonik lanza nuevas micropartículas PEEK

Evonik’s Resource Efficiency Segment’s High Performance Polymers business line has developed innovative polyetheretherketone (PEEK) microparticles, VESTAKEEP 5000HCM, which can improve customized PEEK seals and give them excellent mechanical properties to meet the needs of the oil and gas industry. Standard-sized oil and gas seals made of PEEK are usually processed by injection molding, extrusion and thermoforming (HCM). If the product needs to be customized, manufacturers usually choose thermoforming because it has lower costs associated with downstream manufacturing processes compared to injection molding and extrusion. With the launch of VESTAKEEP 5000HCM, the processing output of thermoforming will be increased and the quality of the finished product will be enhanced. VESTAKEEP 5000HCM, in the form of microparticles, can effectively reduce or even…

2016-09-01 | Noticias, Noticias de la industria | Etiquetas: Noticias de la industria

Changzhou Junhua PEEK recibió financiación del Fondo de Innovación en Ciencia y Tecnología de Changzhou

Recently, Changzhou Junhua Special Engineering Plastic Products Co., Ltd.’s project «Research and Development of Continuous Extrusion Technology for High-Performance Special Polymer PEEK Profiles» received a grant of 100,000 yuan from the Science and Technology Innovation Fund of Changzhou City, Jiangsu Province. The main content of this project is to study the continuous extrusion molding of high-performance special polymer polyetheretherketone (PEEK) profiles, in which the materials mainly include polyetheretherketone (PEEK) and the continuous extrusion process of modified composite materials such as enhanced and lubricated PEE. The profile categories mainly include continuous extrusion research of rods with a diameter of 3 mm to 200 mm, continuous extrusion molding research of plates with a thickness of 5 mm to 15 mm and a…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Aviso de cambio de denominación social y capital social

Considering the development needs of the company, our company name was changed from «Changzhou Junhua Special Engineering Plastic Products Co., Ltd.» to «Jiangsu Junhua Special Engineering Plastic Products Co., Ltd.». The registered capital was increased from 500,000 to 10 million. The company’s contact information, office address, business relationships and service commitments remain unchanged. We sincerely thank you for your consistent support and care for our company. We will continue to maintain a pleasant cooperative relationship with your company and hope to continue to receive your care and support! Best regards! Jiangsu Junhua Special Engineering Plastic Products Co., Ltd. December 5, 2014

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

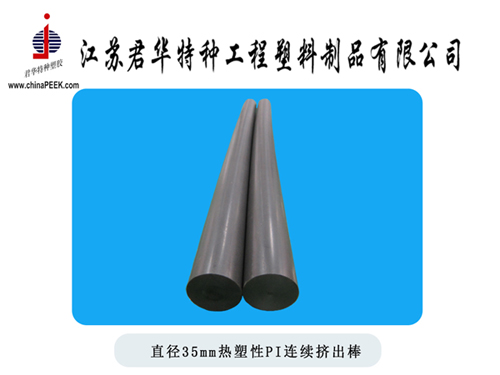

Se extruyeron con éxito varillas de poliimida termoplástica (PI) de forma continua

Polyimide (PI) has excellent resistance to high temperature, low temperature, solvent, radiation, and outstanding mechanical strength and dielectric properties. It has been widely used in many high-tech fields such as aerospace, aviation, automobiles, electronic semiconductors, welding and cutting, and electrical appliances. However, the difficulty in processing and high manufacturing costs of polyimide (PI) have always been two key factors restricting its rapid development. Research and development of melt-processable thermoplastic polyimide (PI) is one of the main methods to enable it to have processing and molding properties and reduce manufacturing costs. Thermoplastic polyimide (PI) not only retains the characteristics of traditional thermosetting PI, but also improves processability. In addition to hot compression molding, it can also be molded by extrusion or…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

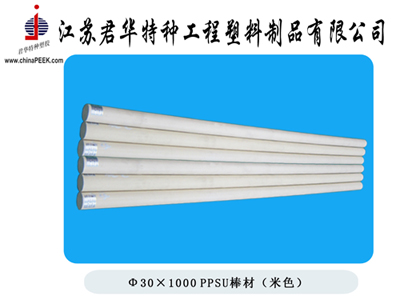

Junhua PEEK extruye con éxito y de forma continua varillas PPSU

Jiangsu Junhua Special Engineering Plastic Products Co., Ltd. successfully continuously extruded PPSU rods. PPSU, scientific name for polyphenylene sulfone resins, is an amorphous high-performance thermoplastic. PPSU is a safe material that does not contain endocrine disrupting carcinogenic chemicals (environmental hormones: bisphenol A). It has good rigidity and toughness, is heat-resistant, heat-resistant and oxidatively resistant, has excellent creep resistance, is resistant to corrosion by inorganic acids, alkalis, and salt solutions, is resistant to ion radiation, is non-toxic, has good insulation and self-extinguishing properties, and is easy to mold and process. PPSU is now widely used in food processing machinery, medical equipment, electronic and electrical industry, chemical processing and other fields. Such as: PPSU integrated circuit board, PPSU coil tube rack, PPSU…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Junhua PEEK PEEK pasó la prueba de certificación de grado alimenticio de la FDA de EE. UU.

On May 29, 2015, Junhua PEEK PEEK passed the US FDA food grade certification test of the US NSF (National Sanitation Foundation: an authoritative organization in the field of public health and safety). Why do we need FDA food grade certification The high-performance plastic parts of PEEK (polyetheretherketone) polymer and its composite materials developed by our company have been widely used in food processing machinery and are food contact materials. The test results can be used for customs clearance of products exported to the United States, and can also be submitted when the FDA may inspect production facilities. (Food contact materials refer to all materials that can come into contact with food during the processing, production, packaging, storage and transportation…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Jiangsu Junhua: Hacemos lo que otros no pueden hacer

At this rubber and plastics exhibition, Jiangsu Junhua Special Engineering Plastics Products Co., Ltd. exhibited many different brands of high-performance plates, rods, segments and other profiles, which attracted the attention of many merchants. Junhua PEEK is a domestic manufacturer of PEEK plates, rods, tubes, sheets and other profiles and finished parts. The company’s products have been widely used in the fields of automobiles, electronic semiconductors, textile printing and dyeing machinery, packaging machinery, medical equipment, and petrochemical machinery. Li Jun, general manager of Jiangsu Junhua Special Engineering Plastic Products Co., Ltd., said that the PEEK material produced by the company has the properties of high temperature resistance, high strength, self-lubrication, wear resistance, hydrolysis resistance, and corrosion resistance, and the electrical properties…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Junhua PEEK aprobó la certificación nacional de empresa de alta tecnología

Recently, our company received a notice from the Wujin Science and Technology Bureau of Jiangsu Province: According to the relevant provisions of the «High-tech Enterprise Recognition Management Measures» and «High-tech Enterprise Recognition Management Guidelines» of the Ministry of Science and Technology, the Ministry of Finance, and the State Administration of Taxation, after successful application and review, Jiangsu Junhua Special Engineering Plastic Products Co., Ltd. was officially recognized as a high-tech enterprise. The high-tech enterprise certification is jointly established by the Ministry of Science and Technology, the Ministry of Finance, and the State Administration of Taxation. The purpose is to standardize and unify the national certification of enterprise qualifications. The certification threshold for high-tech enterprises is much higher than that of…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa

Junhua PEEK PEEK pasó la prueba de certificación de grado alimenticio de la FDA de EE. UU.

On August 16, 2018, Junhua PEEK PEEK passed the food grade certification test of the U.S. Food and Drug Administration (FDA). What is the FDA FDA is the abbreviation of the U.S. Food and Drug Administration. It is one of the executive agencies established by the U.S. government in the Health and Human Services and Public Health Stations. Internationally, FDA is recognized as the world’s food and drug administration agency. Many other countries promote and monitor the safety of their own products by seeking and accepting the help of FDA. The high-performance plastic parts of PEEK polymers and their composite materials developed by our company have been widely used in food processing, pharmaceuticals, medical devices (non-implant grade) and…

2016-09-01 | Noticias, Noticias de la empresa | Etiquetas: Noticias de la empresa