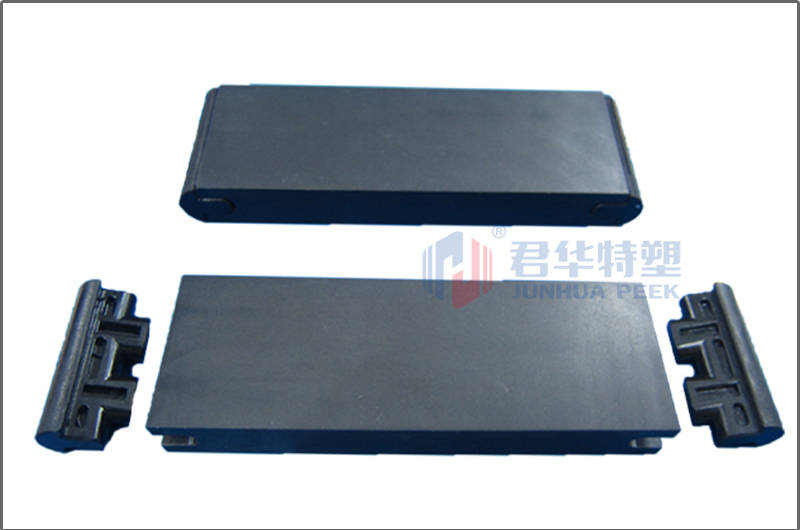

Control deslizante y conector de bomba de vacío YTZ-07

The main trends in the industry are: improving performance and efficiency, reducing weight and miniaturization while reducing costs. In gear applications, engineers are looking for new materials to replace existing metal materials, or to improve typical polymer material solutions to meet the high requirements of future systems for high performance. Because different types of loads are always sent at the same time, gears need to meet multiple complex needs. The normal operation of gears depends on good friction and mechanical properties, resistance to corrosive media, durability and heat resistance, and dimensional accuracy.

Polyetheretherketone ( PEEK ) is a new type of high-performance special engineering plastic. Its English name is PolyetheretherKetone. It is a high-performance material first synthesized and patented by Victrex, a British company. It has a history of more than 30 years of production and use.

◆ High temperature resistance – the long-term use temperature certified by UL in the United States is 260°C. Even when the temperature reaches 300°C, it can still maintain good mechanical properties.

◆ Wear resistance – In many extremely harsh application environments such as high temperature, high load, and strong corrosion, PEEK polymers and their composite materials have good wear resistance.

◆ Self-lubricating – It has a low friction coefficient, can achieve oil-free lubrication, and can work for a long time in media such as oil, water, steam, weak acid and alkali.

◆ Corrosion resistance – insoluble in common solvents, and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ High strength: It has good mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Easy to process – parts can be directly processed by injection molding process. Post-processing such as turning, milling, drilling, tapping, bonding and ultrasonic welding can be performed.

◆ Hydrolysis resistance – Even in steam over 250°C or immersed in high-pressure water, PEEK products can still work continuously for thousands of hours without significant performance degradation.

◆ Flame retardancy – Without using any additives, the flammability rating of the 1.45mm thick PEEK sample is UL94 V-0.

◆ Low smoke and non-toxic – the amount of smoke and toxic gas during combustion is extremely low.

◆ Electrical performance: It can maintain stable and excellent electrical performance over a wide range of temperature and frequency.

◆ Radiation resistance – It has extremely strong resistance to high-dose gamma-ray radiation, and its mechanical properties can be completely preserved, so it can be used as radiation-resistant parts.

◆ Dimensional stability

◆Low noise

In recent years, Junhua PEEK PEEK high-performance polymer materials have been successfully used as a substitute material in a wide range of industries. In response to the continued development of this trend, Jiangsu Junhua has sufficient resources to develop processing, design and application.

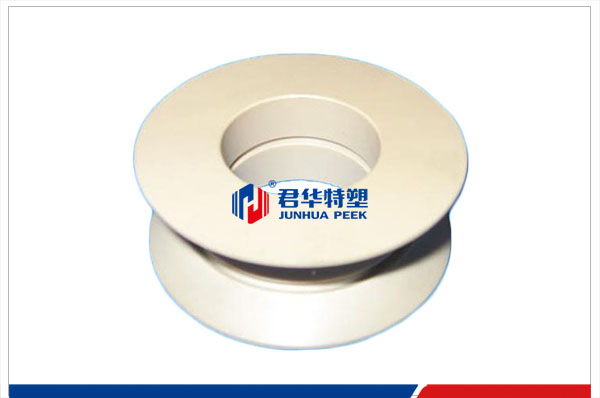

The existing processing technologies include gear hobbing, direct injection molding, gear shaping and other processes.