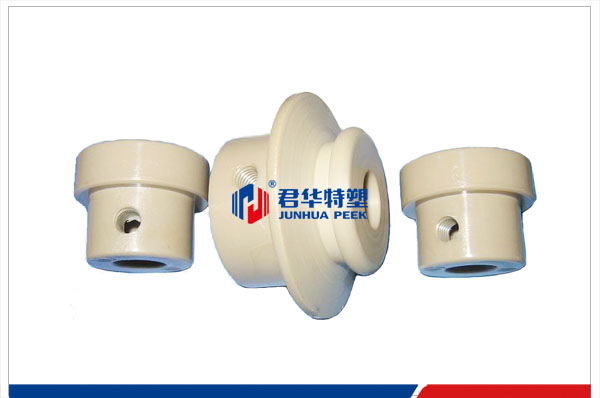

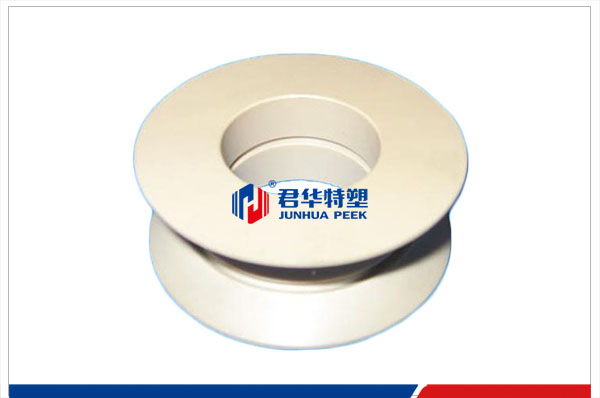

Bloque deslizante PEEK

1. Overview:

PEEK is a high temperature resistant thermoplastic with a high glass transition temperature (143°C) and melting point (334°C). Its load thermal deformation temperature is as high as 316°C (30% glass fiber or carbon fiber reinforced grades).

2. Detailed description:

Main characteristics and advantages of PEEK:

1: High temperature resistance The long-term use temperature of the US UL certification is 260°C. Even when the temperature reaches 300°C, it can still maintain good mechanical properties.

2: Wear resistance In many extremely harsh application environments such as high temperature, high load, and strong corrosion, PEEK polymers and their composite materials have good wear resistance.

3: Self-lubrication has a lower friction coefficient, can achieve oil-free lubrication, and can work for a long time in media such as oil, water, steam, weak acid and alkali.

4: Corrosion resistance : Insoluble in common solvents, and has good corrosion resistance to various organic and inorganic chemical reagents.

5: High strength : It has good mechanical strength among plastics. It also has high rigidity and surface hardness.

6: Easy to process: Parts can be directly processed by injection molding process. Post-processing such as turning, milling, drilling, tapping, bonding and ultrasonic welding can be performed.

7: Hydrolysis resistance: Even when immersed in steam at a temperature exceeding 250°C or in high-pressure water, PEEK products can still work continuously for thousands of hours without significant performance degradation.

8: Flame retardancy Without using any additives, the flammability grade of the 1.45mm thick PEEK sample is UL94V-0.

9: Low smoke and non-toxic The amount of smoke and toxic gas during combustion is extremely low.

10: Electrical properties can maintain stable and excellent electrical properties within a wide temperature and frequency range.

11: Radiation resistance: It has strong resistance to high-dose gamma-ray radiation, and its mechanical properties can be fully retained, so it can be used as radiation-resistant parts.

12: Dimensional stability