Hoja PAI

PAI Board:

The English name is Polyamide-imide, which is a new type of engineering plastic containing amide groups. Because polyimide molecules have a very stable aromatic heterocyclic structure, it exhibits heat resistance and low temperature resistance that other polymer materials cannot match. In high temperature environments, it has good mechanical properties and dimensional stability.

Features:

- Works well from low temperature to 260 degrees Celsius

- Excellent mechanical strength

- Ease of processing

- Low flammability and low smoke generation

- Fatigue strength

- Impact strength

- Creep resistance

- Wear-resistant

- Low expansion coefficient

- Excellent thermal stability

- Resistance to aviation and automotive fluids

PAI brand:

| Brand | Add ingredients | Features | application |

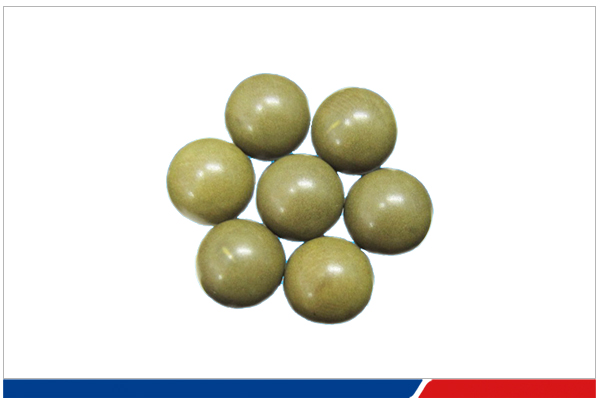

| GOOD | TiO2 | Good impact resistance, high elongation, good mold release and electrical properties. | Connectors, switches, relays, thrust washers, spline bushings, valve seats, check balls, poppets, mechanical connections, bushings, wear rings, insulators, cams, picker claws, ball bearings, rollers and thermal insulators |

| PAI-GF30 | 30% Glass Fiber | High rigidity, good rigidity retention at high temperatures, very low creep and high strength. | Built-in sockets, gears, valve plates, fairings, pipe clamps, impellers, rotors, housings, protective washers, terminal boards, insulators and brackets |

| PAI-CF30 | 30% Carbon Fiber | Good rigidity retention at high temperatures, good fatigue resistance, and electrical conductivity. | Replaces metal, housings, mechanical connections, gears, fasteners, spline bushings, cargo rollers, brackets, valves, labyrinth seals, fairings, pipe clamps, standoff insulators, impellers, shrouds, potential EMI shielding |

PAI sheet size:

| Serial number | Material | Specifications (mm) | unit |

Reference thickness |

| 1 | GOOD | T2*300*300 | kg | 2.2 |

| 2 | GOOD | T3*300*300 | kg | 3.3 |

| 3 | GOOD | T5-T12*300*300 | kg | 5.4/6.4/7.8/10.8/12.8 |

| 4 | GOOD | T15/T20*300*300 | kg | 15.8/20.8 |

| 5 | GOOD | T50*300*300 | kg |

PAI material application areas:

PAI is often used in the production of precision parts for high-tech equipment and in situations where wear resistance is extremely high, such as the electronic semiconductor industry; it is used in products that work under high temperature, high vacuum, strong radiation, and ultra-low temperature conditions, such as aerospace and oil drilling equipment.

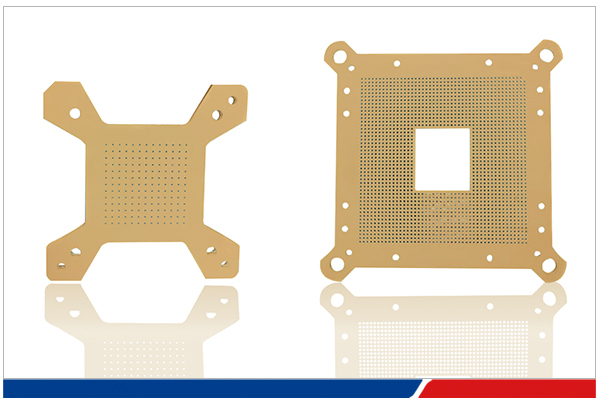

01. Semiconductor test components, processing nests, wafer combs

02. Microelectronic IC test socket and contactor

03. Seals, pump and valve components, bearings and bushings

04. Scientific instrument parts, other electronic components

05. Electrical connectors, aerospace components

06. Bushings, bearings, sockets or structural parts in demanding applications

07. Insulation and passivation layers in digital semiconductors or structural parts in MEMS chip manufacturing