Partículas PEEK de grado médico para implantes AKSOPEEK

PEEK synthesis process: In a non-protonic polar solvent, diphenyl sulfone is used as the solvent, 4,4′-difluorobenzophenone and hydroquinone are used as monomers in the presence of alkali metal carbonates, and the resulting product is polycondensed at high temperature. The initial PEEK raw material after synthesis contains a large amount of monomers, additives and various by-products. The PEEK raw material needs to be further purified to remove impurities before it can be used as a medical raw material. Medical-grade PEEK materials can be divided into medical-grade PEEK5600G and implant-grade AKSOPEEK according to their purified purity and material properties .

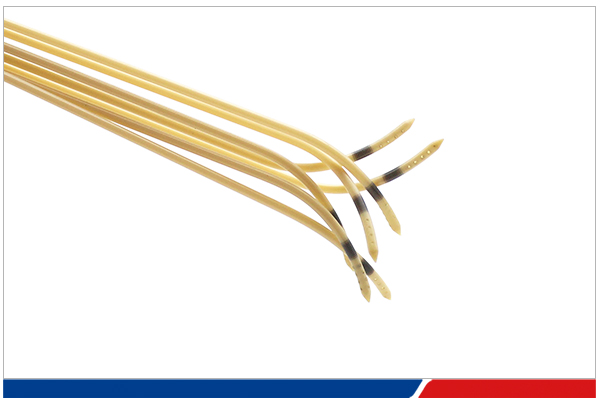

Medical-grade PEEK: This grade of PEEK material is currently mostly used in external fixation devices that come into contact with the human body surface (such as limb fixation orthopedic stents), short-term interventional PEEK catheters, various circulatory equipment pump parts, and oral stents, teeth and other non-implant consumables. This type of application scenario generally requires PEEK materials to have a certain degree of biosafety, such as no cytotoxicity, no allergic reaction, no irritation or intradermal reaction, and also should meet the corresponding mechanical performance requirements.

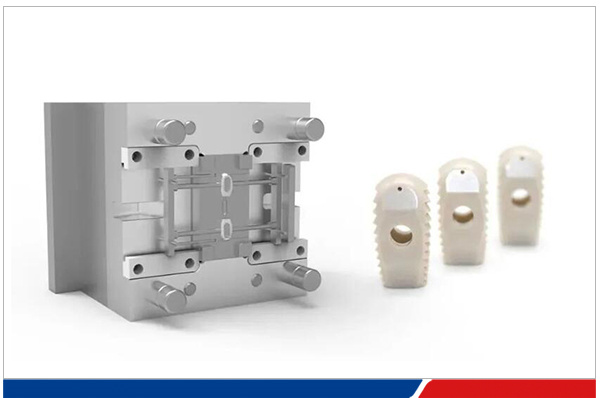

Implant-grade PEEK: As the name implies, PEEK materials that can be used to prepare «implant devices» are called implant-grade PEEK. This type of material is commonly used in orthopedic implant consumables (such as intervertebral fusion devices, ligament repair anchors, joint interface screws), neurosurgery patches (such as artificial skulls, maxillofacial bones), and cardiovascular products (such as heart valves, pacemaker housings, etc.). In recent years, modified PEEK materials have begun to be widely used in oral implants, traumatic bone plates and other products with high mechanical performance requirements. In addition to meeting the biocompatibility of medical-grade PEEK, implant-grade PEEK should also have more stringent biosafety requirements, such as systemic toxicity, genotoxicity, carcinogenicity, blood compatibility, and implantation reactions, and must also comply with the requirements of «YY/T 0660-2008 Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implants».

AKSOPEEK

China’s implant-grade PEEK materials mainly rely on imports. Based on market feedback and national R&D project needs, Junhua PEEK has launched the domestic implant-grade PEEK material brand AKSOPEEK series of products.

Based on the present and looking to the future. In 2018, Changzhou Junhua Medical officially launched the implantable PEEK project. At present, it has obtained complete third-party reports on biology, physicochemistry, aging, etc. In order to better standardize implantable PEEK, it has added implantable AKSOPEEK series grades.

1) AKSOPEEK Natural : Implant-grade PEEK pure material

2) AKSOPEEK HA : Hydroxyapatite improves the biocompatibility of implantable PEEK materials

3) AKSOPEEK CF : Chopped carbon fiber implant grade PEEK material

4) AKSOPEEK LCF : Continuous carbon fiber implant grade PEEK material

Company advantages

1. As one of the earliest domestic companies engaged in the research, development, and production of PEEK materials, Jiangsu Junhua pays great attention to the application of PEEK in the medical industry and has been committed to the research, development, and production of medical implant-grade PEEK materials. It can supply implant-grade PEEK material particles, rods, plates, and 3D printing PEEK filaments.

2. After 16 years of production and technology accumulation, the company started from the source of polymerization and established Shandong Junhao High Performance Polymer Co., Ltd. to develop polymer implantable PEEK raw materials.

3. A GMP refining production workshop was established in accordance with the production standards for medical implant materials, and refining and purification equipment for implant-grade AKSOPEEK polymerization was developed, which effectively solved the problem of excessive heavy metal ion content in implant PEEK materials.

4. The company started pilot production of implantable-grade PEEK materials in 2020. In the same year, it conducted third-party tests on various biological aspects of the materials in accordance with ISO10993 testing standards, and all test results met the requirements.

5. In 2021, Junhua sent the first batch of mass-produced implantable-grade AKSOPEEK to a third party for inspection in accordance with the national requirements for implantable PEEK materials «YY/T 0660-2008 Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implants», and obtained a complete third-party test report on implantable PEEK materials to ensure that the material can be effectively replaced in terms of physical and chemical properties and biology.

Application Scenario

The domestically produced medical implant-grade PEEK material AKSOPEEK has excellent physical and chemical properties, and its radiotransparency, biocompatibility and human bone matching are no less than similar foreign products, achieving import substitution of PEEK materials in the fields of orthopedic tumors, plastic surgery, spine, knee joints and craniofacial repair.